AC3000/4000 System

Optimize Sample Transport and Quality Control Processes

Aerocom’s fully automatic AC3000 system is a perfect fit for organizations that require quality control. With its slow speed and soft delivery options, you can safely transport sensitive items such as solid and liquid samples, hot samples, sensitive electronic equipment, pharmaceuticals, sugar and other powders, IV solutions, and whole blood or plasma.

Large and small industries can reduce or eliminate the foot traffic caused by periodic product sampling throughout each shift, boosting productivity, increasing safety, and improving the overall bottom line. Common industries that may benefit from the AC3000 include:

- Manufacturing

- Processing Plants

- Foundries

- Casinos

System Features

- Fully automatic system

- Computer controlled (Windows-based)

- Single- and multiple-zone configurations

- Up to 512/100 Stations on up to 128 zones

- Unlimited configuration of transfer points between zones

- Secure send for limiting access to a sent carrier

- Slow speed for transporting sensitive items

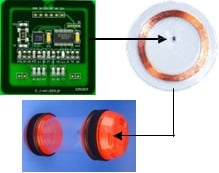

- RFID carrier tracking

- RFID user tracking

- Complete carrier audit trail

System Benefits

The AC3000 optimizes your organization’s internal logistics; provides real-time carrier tracking and audit trail reporting; reduces safety and security hazards by eliminating foot traffic; and offers multi-zone configuration for simultaneous carrier transfer. Explore a few other ways Aerocom helps organizations improve operational efficiency and save money with pneumatic tube systems.

Optimizes Time and Space

The AC3000’s unique sending and receiving stations minimize the amount of tubing needed to configure your system. Because the Titan station can function as a pass-thru unit, carriers travel through several floors without the need of being routed through other system diverters and direct connect units. This technology saves time in carrier transfer and coveted space in the interstitial areas.

Low-Voltage

The AC3000 is powered through a central power supply and from that point is stepped down to 24 volts DC. There is no need for additional data cable ports or 110v outlets at each station or diverter location, which can save thousands of dollars in electrical work.

RFID Technology

Aerocom offers the use of RFID-tagged carriers, which labels each carrier with a unique identifier that assigns it a “home” station. This allows the carrier to automatically return to its original location when inserted back into the system.

Aerocom offers the use of RFID-tagged carriers, which labels each carrier with a unique identifier that assigns it a “home” station. This allows the carrier to automatically return to its original location when inserted back into the system.

Once a carrier has traveled through 3000 transactions, the RFID tracking device alerts the system and automatically pulls the carrier out of service for regular maintenance. Detailed reports can be created and analyzed from this tracking feature, further optimizing system procedures.

The AC3000 supports the following RFID tags: Mifare 1k, Mifare 4k, UltraLight, DesFire, NFC NTAG203.

Why Choose Aerocom USA?

Custom Solutions

We work with trained architects to design, manufacture, and install custom systems that are the perfect fit for your organization.

Durable Products

We develop high-quality systems and products with the widest range of user features and reliability.

24/7 Support Line

We’re dedicated to keeping your system in perfect working order. Our team is available around the clock to fulfill maintenance requests and answer questions.

Experience You Can Trust

We work with trained architects to design, manufacture, and install custom systems that are the perfect fit for your organization.